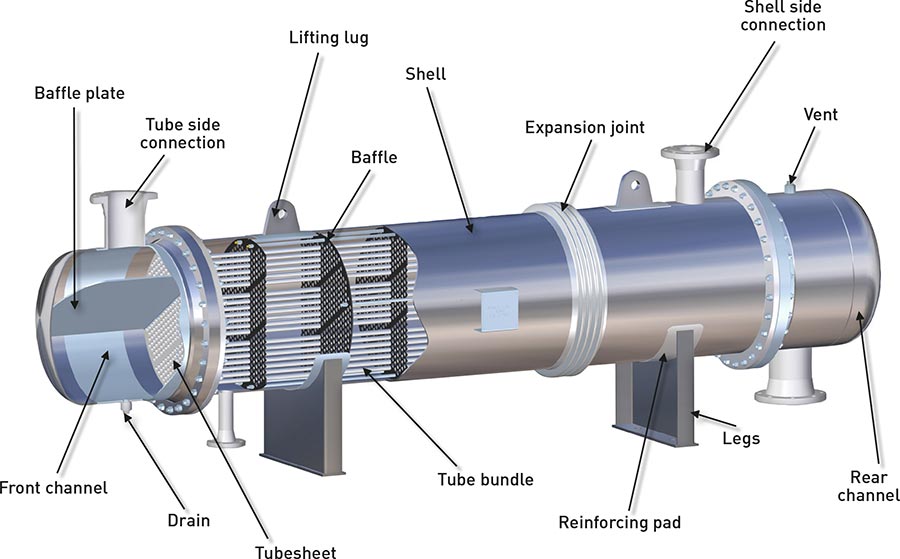

Heat exchangers are used to transfer heat efficiently from one medium to another. They are typically used in many commercial/industrial applications.

There are many types of heat exchangers. The two most common types are tube and shell heat exchangers and plate and frame heat exchangers. Properly maintaining your facility’s heat exchangers can save your facility money, downtime and repairs. Maintenance service is mostly scheduled to be performed at regular intervals for cleaning and inspection. However, in case of leakage/loss of efficiency exchangers are directly subjected to maintenance.

Every type of heat exchanger has its own specific protocol when it comes to maintenance and troubleshooting and there are a host of common problems that can occur. Over time, sediment and grime can build up on plates or tubes and cause clogs, retard heat transfer and reduce efficiency. Corroded gaskets, uneven plate pack clamping, pressure losses, blockage and fouling are all issues that can eventually plague your system’s heat exchanger.

Technium has many years of experience in heat exchanger maintenance and our services include:

- Disassembly/assembly

- Hydrostatic Testing

- Tube Isolation

- Torque & Bolt Tensioning

Get in touch

We always stand at your disposal to provide you with more information, answer any questions you may have and create an effective solution for your industrial needs.